products

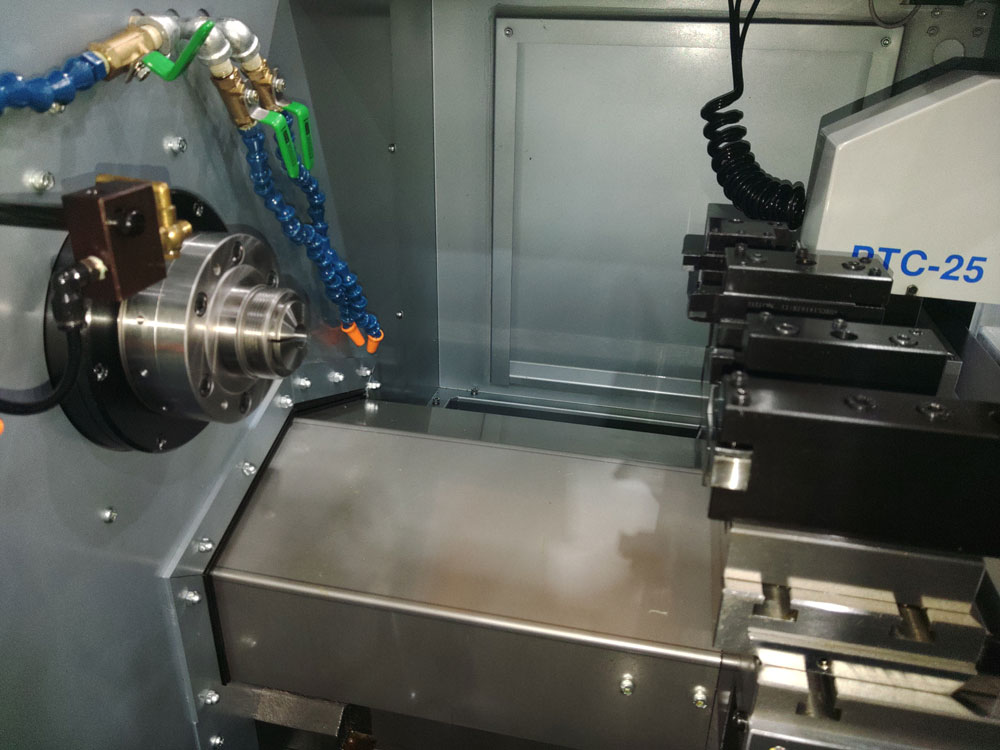

NUCROBO-202Robot-equipped automated CNC lathes

products

NUCROBO-202

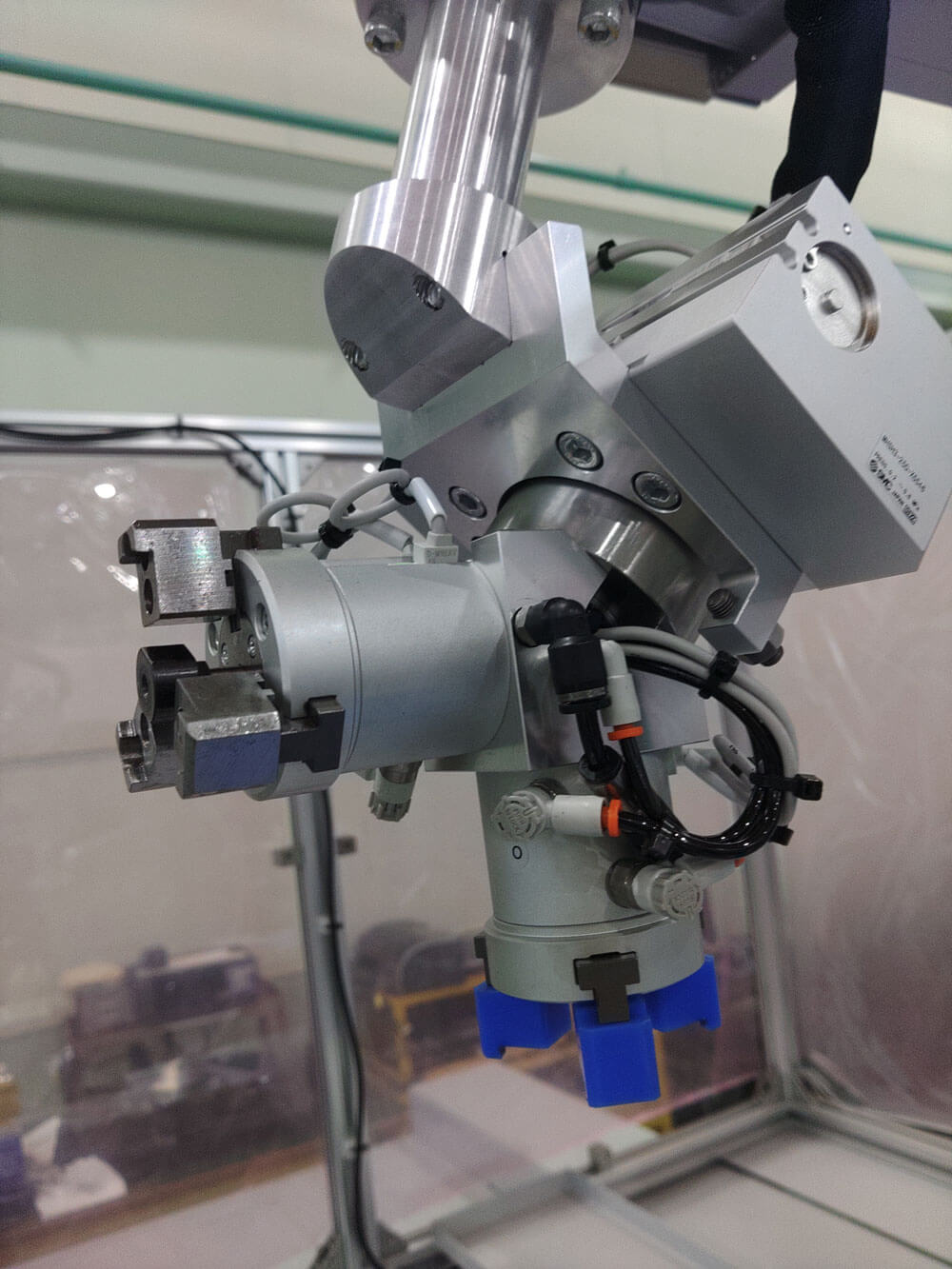

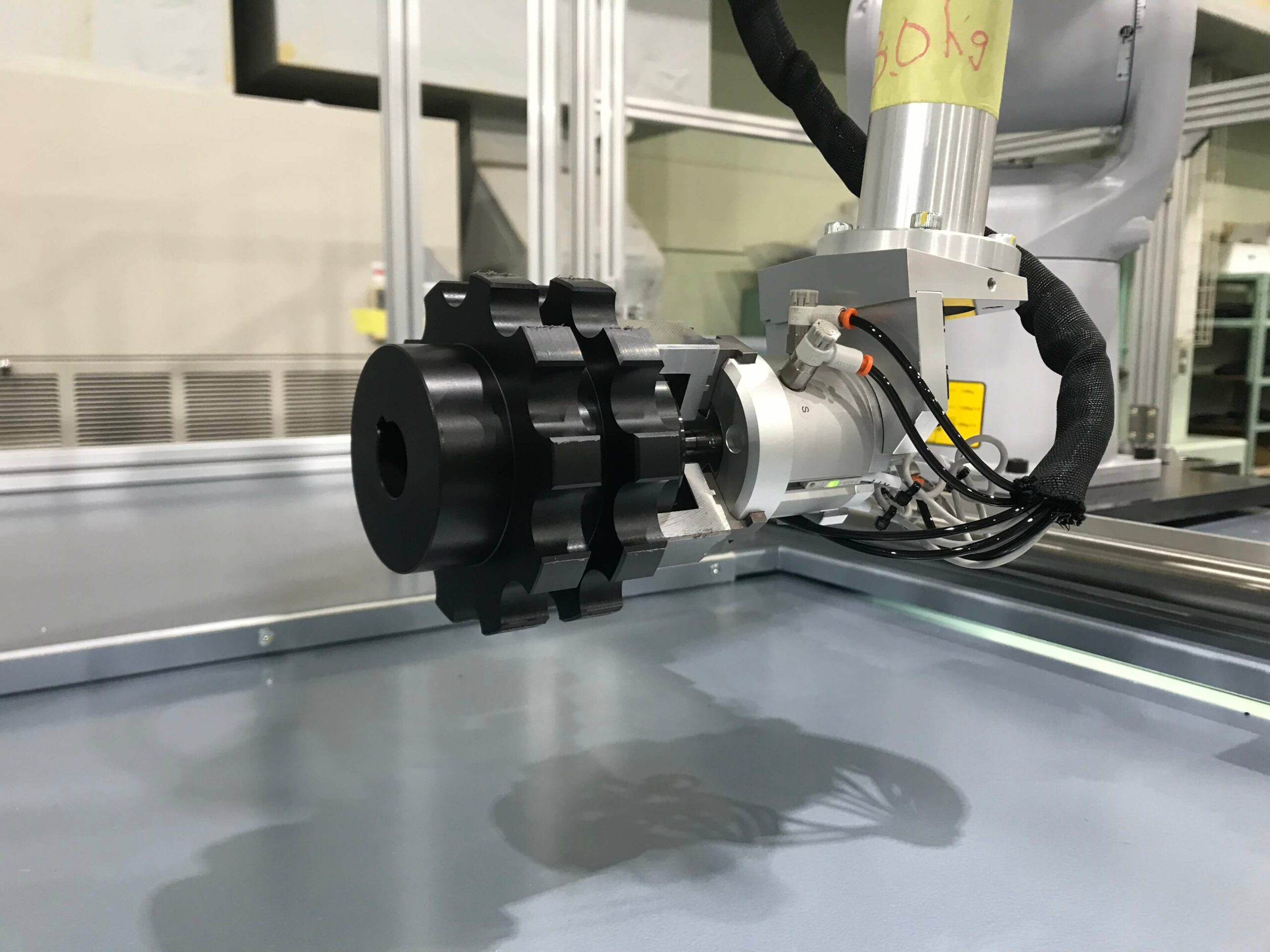

EGURO robot system

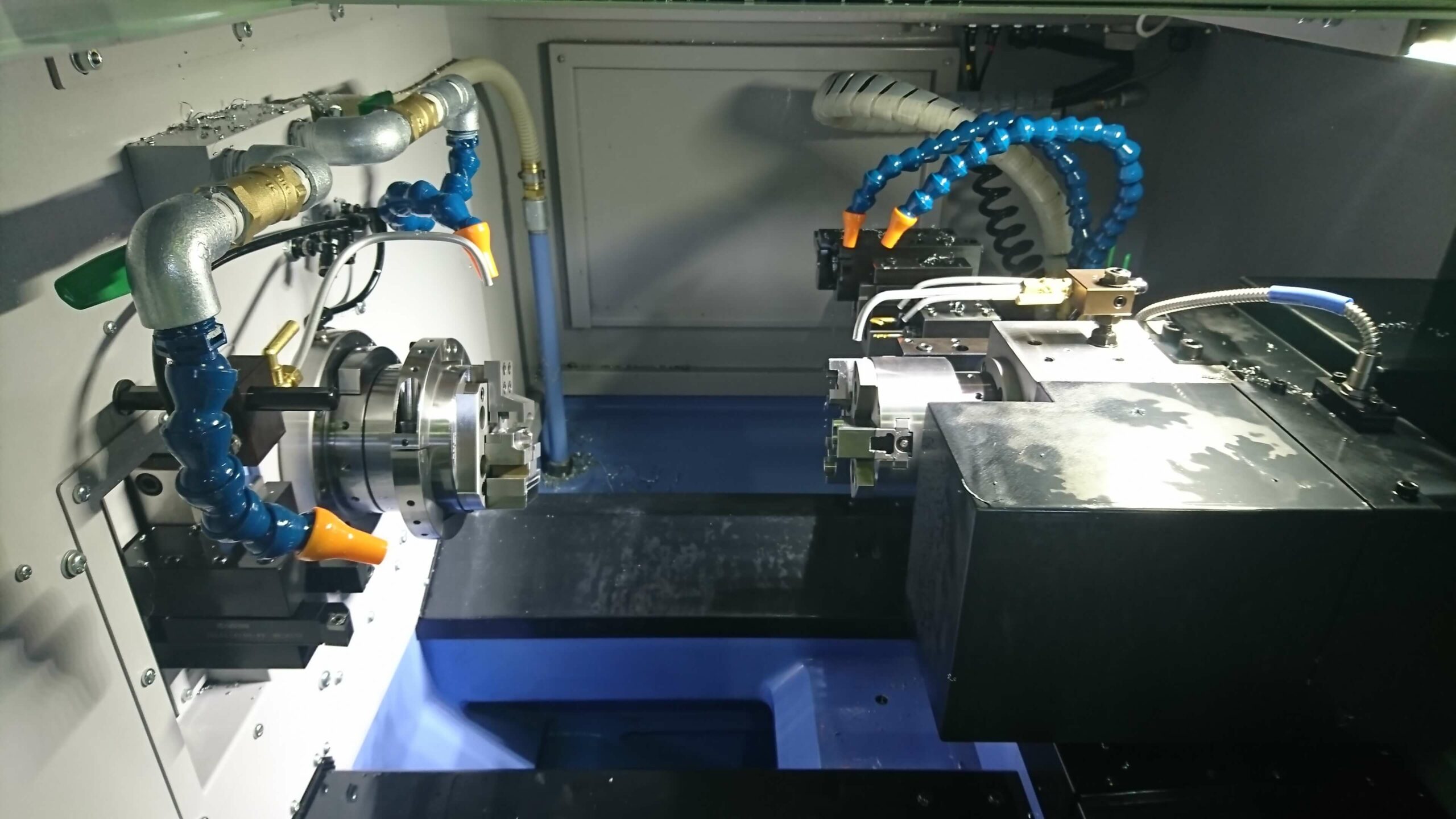

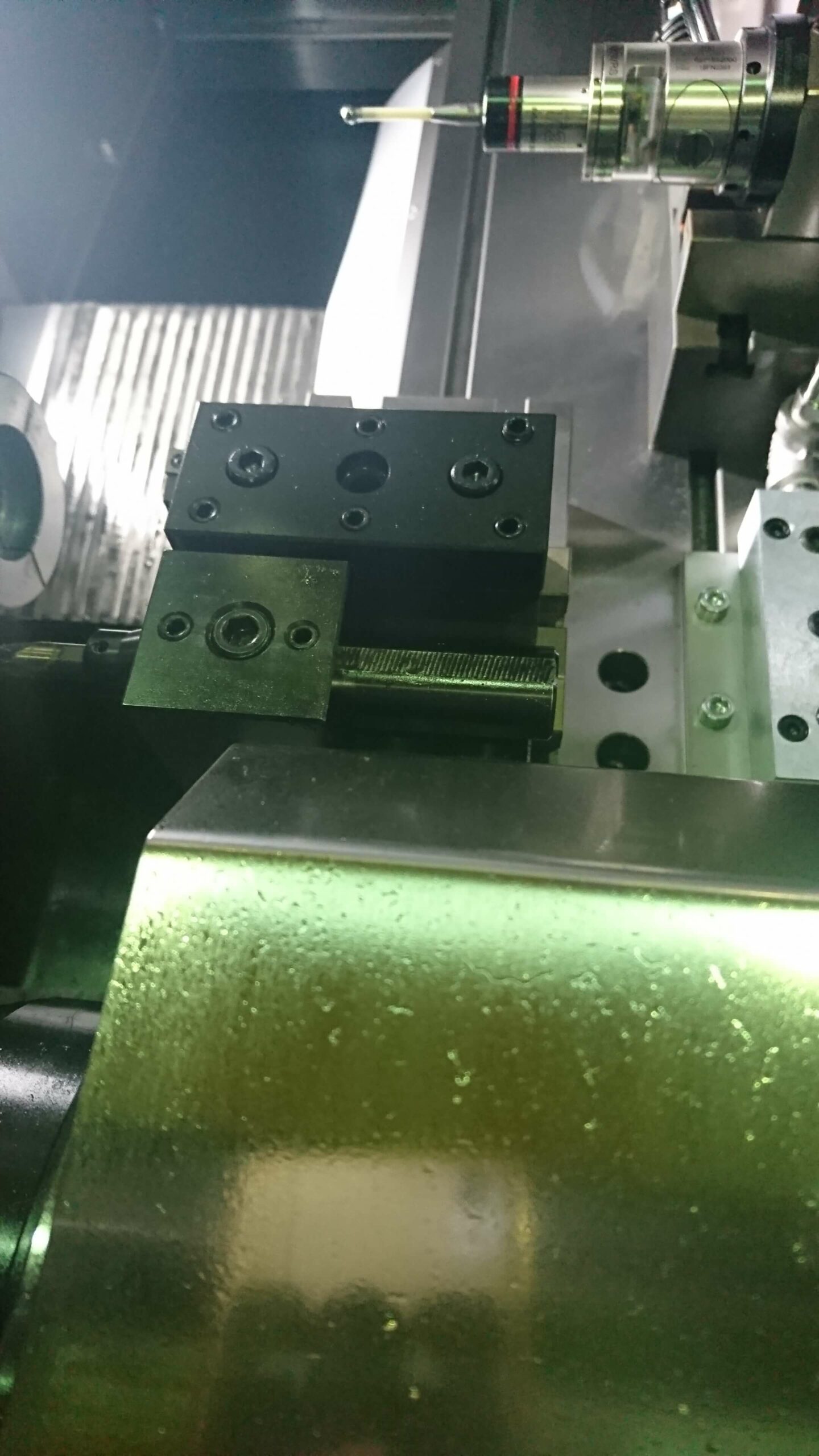

CNC lathe with machinery-robot integration featuring the longest stroke

Reliable precision

- Closed-loop specification with optical scale delivering 0.05-μm resolution on the X-axis

- Stable machining accuracy even from cold start

Extensive range of options available

- Wide range of options for stroke size, spindle speed, etc.

- Extensive specialized options tailored to specific machining applications

Machinery-robot integration ensures restorability and positional accuracy

- The multi-joint robot is fixed to the mechanical leg section to ensure stable precision

- Quick restoration after delivery or relocation

For more information or inquiries about this product, please contact us here.

| Category | NUCROBO-202 | Unit | |

|---|---|---|---|

| Capacity | Maximum machining range (diameter × length) | φ80×60 | mm |

| Spindle | Rotation speed conversion ratio | Stepless S4-digit direct command | |

| Rotation speed | Max. 6,000 | min-1 | |

| Spindle nose | EDA-10 collet type | ||

| Cutting table | X-axis travel | 420 | mm |

| Z-axis travel | 390 | mm | |

| X-axis rapid traverse rate | 15 | m/min | |

| Z-axis rapid traverse rate | 15 | m/min | |

| Control method | 1-μm closed loop (X-axis) | ||

| Jog feed rater | 0~1,287 | mm/min | |

| Number of tools | Depends on workpiece shape | ||

| Toolpost | Gang-type | ||

| Electric motor | Drive system | Belt drive | |

| Output | 5.5/3.7 (30-minute/continuous) | KW | |

| Toolpost (X-axis) | 1.4 | KW | |

| Toolpost (Z-axis) | 2.7 | KW | |

| Main unit specifications | Power supply | 16.0 | KVA |

| Height from floor to spindle center | 1,035 | mm | |

| Unit height | 1,645 | mm | |

| Required floor space (width × depth) | 2,025×1,870 | mm | |

| Unit weight | 2,200 | Kg | |

| Control device | FANUC System Oi-TF PLUS | ||

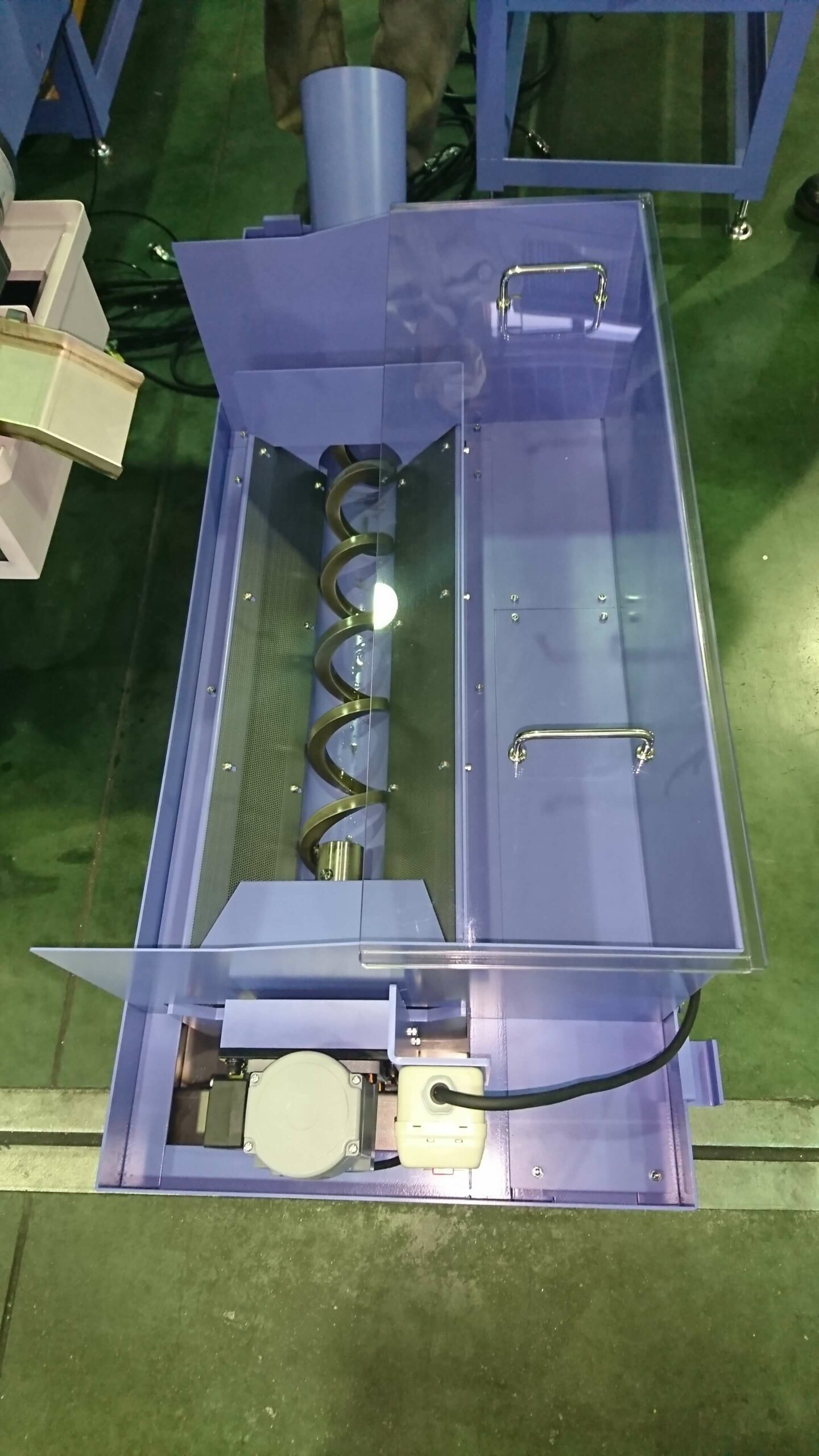

Robot-type machinery (with vertical multi-joint robots)

EGURO has been actively engaged in robot-based automation since the 1980s and has built an impressive track record spanning many years.

We offer CNC lathes equipped with vertical multi-joint robots as solutions featuring machinery-robot integration.

Space saving is achieved with this approach to integration as well. We also offer proposals of stocker devices, safety equipment, and more to meet customers’ requirements.

We provide comprehensive support with both hard and soft aspects, including special training on robots and programming/teaching to facilitate the smooth introduction of robots as “co-workers.”

| Model | Rotation speed (rpm) | Stroke X-axis/Z-axis (mm) | Unit dimensions (mm) Width x depth x height | Weight(kg) |

|---|---|---|---|---|

| 6,000 | 270/270 | 1,685x1,570x1,500 *1 | 2,000 *1 | |

| 6,000 | 260/300 | 1,675×1,500×1,645 *1 | 1,200 *1 | |

| 4,500 | 230/250 | 2,150×1,500×2,050 | 1,200 |