products

E-32vMachining centers with 5-axis control

products

E-32v

Reaching ever higher heights in high-precision machining:

Simultaneous 5-axis control for everything from multi-faceted machining to 3D curved surface machining

High precision

- Thermally symmetric design and rigid gantry structure

- Composite guide surface combining the advantages of both sliding and rolling surfaces maintains spindle accuracy

- Standard specification includes magnetic scales on three axes to ensure stable repeatability and tracking precision

Compact design

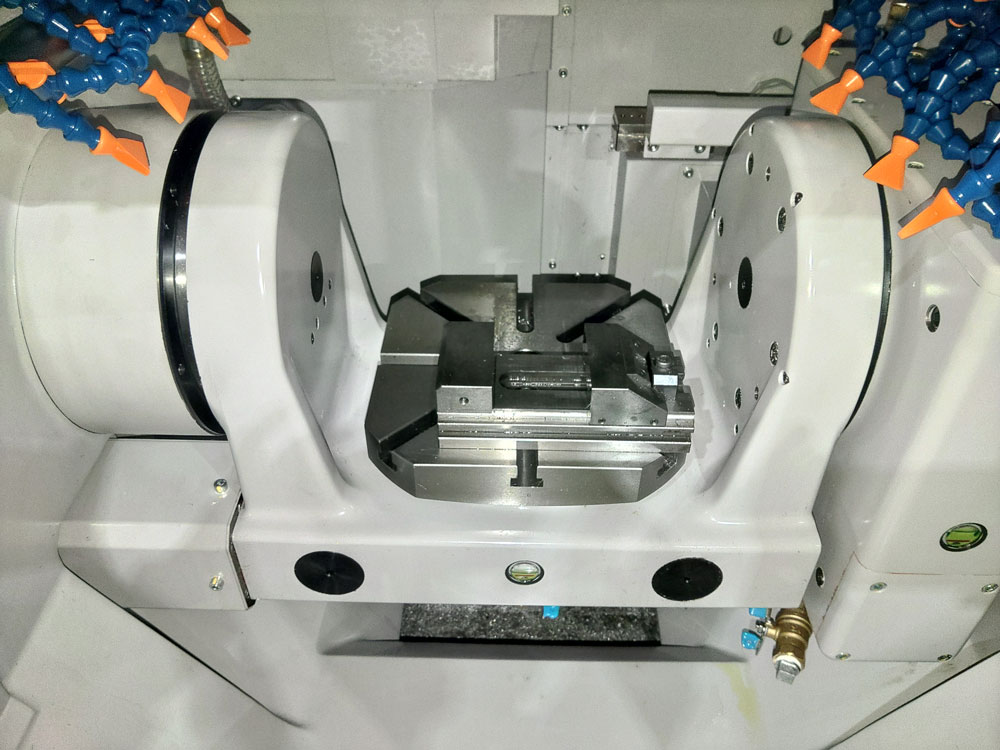

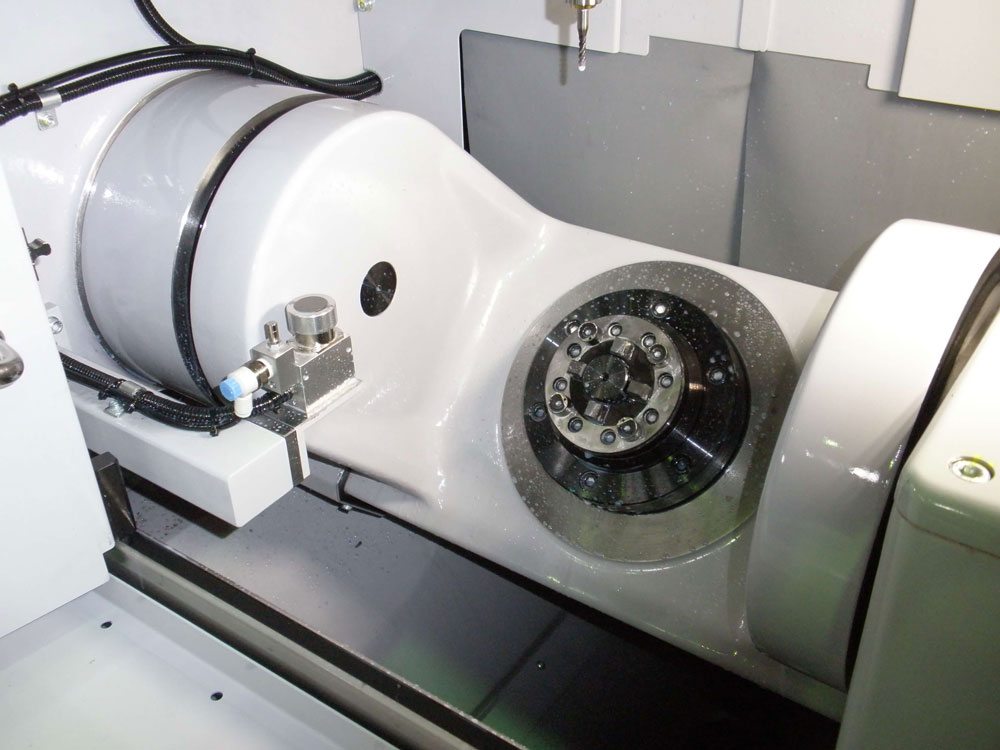

- Maintains compactness and high precision through an innovative trunnion structure

- The basic structure measures 1,000 mm × 1,225 mm but features a stable gantry structure weighing 3.8 tons

Automation compatibility

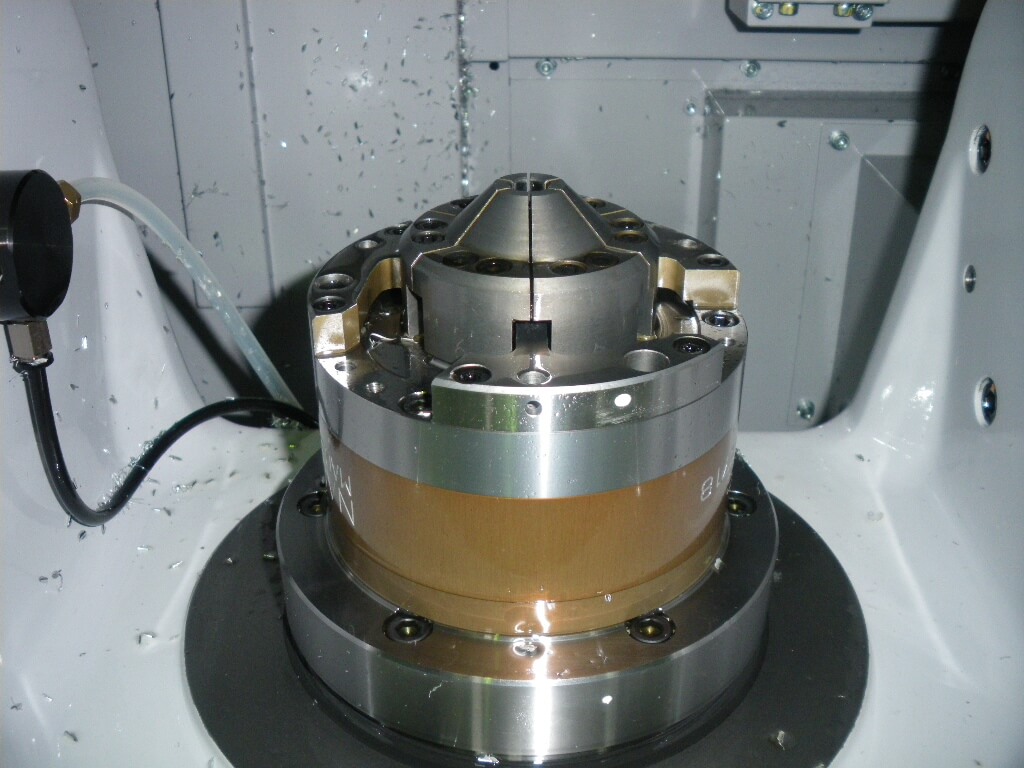

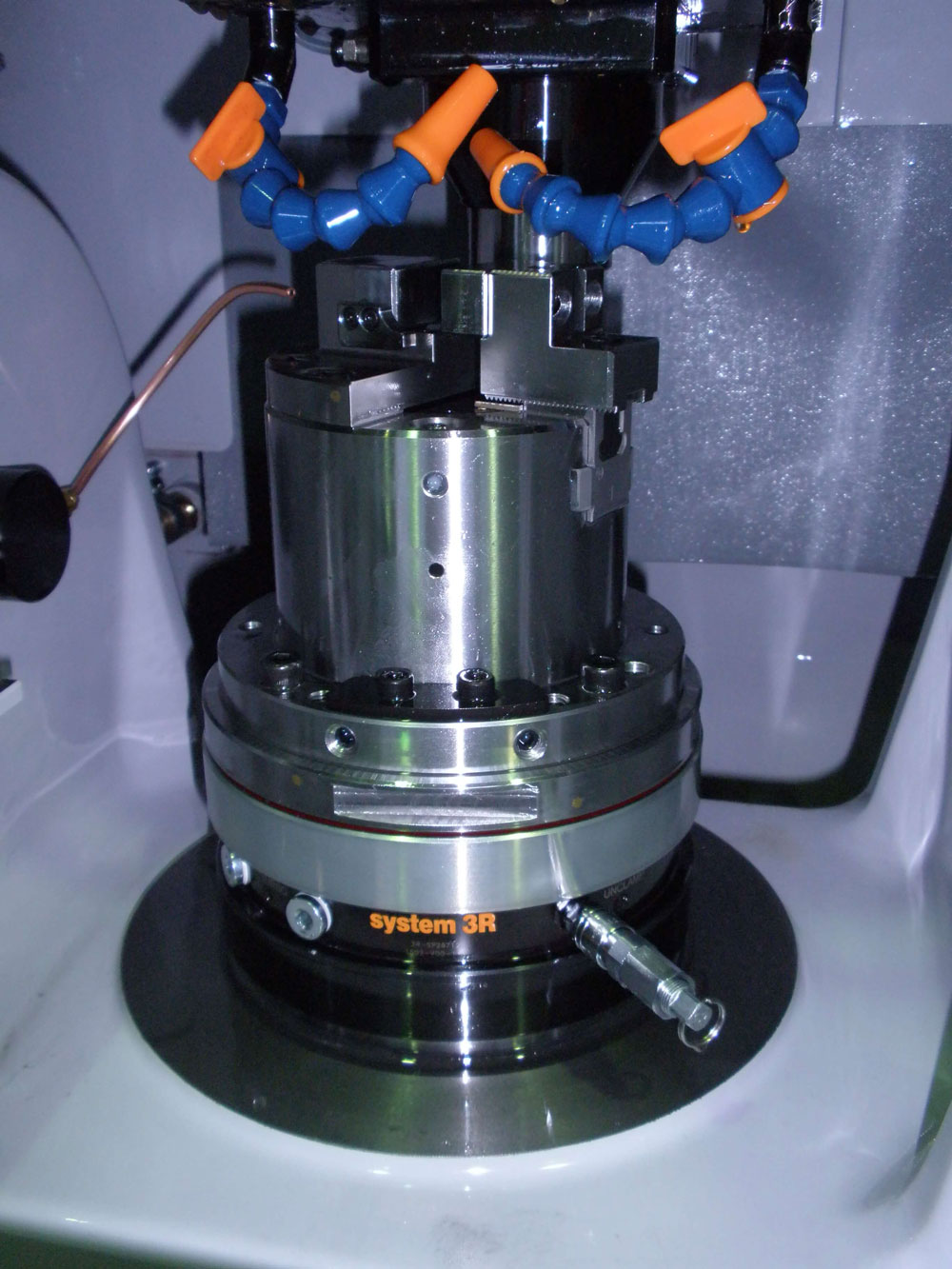

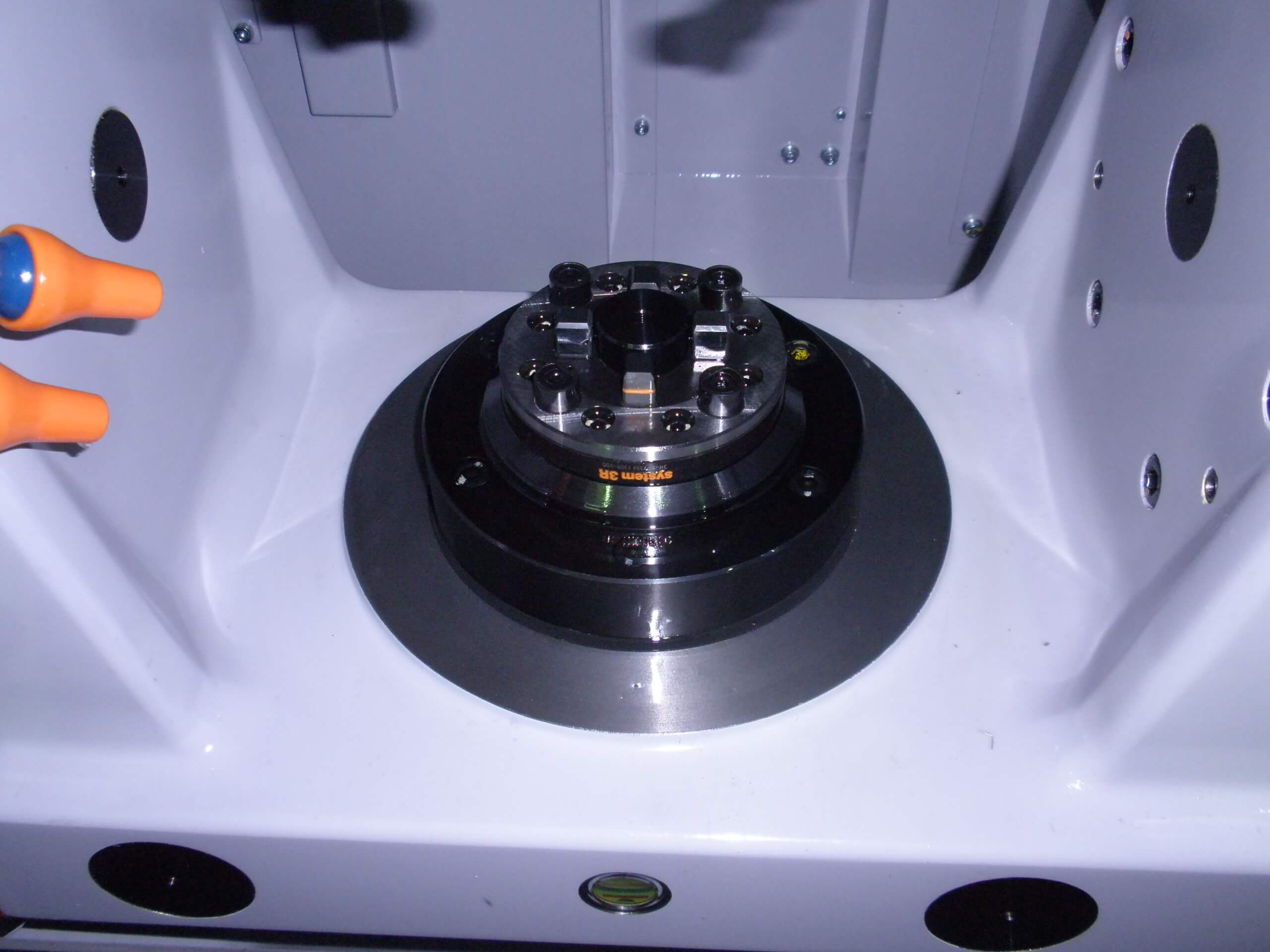

- Tooling options tailored to specific applications with a lineup including high-precision MacroHP chucks manufactured by System3R

- Unmanned system (ROBO-Station) utilizing a vertical multi-joint robot

- EGURO provides comprehensive support from system design to manufacturing, automation, and after-sales service

For more information or inquiries about this product, please contact us here.

| Category | E-32v | Unit | |

|---|---|---|---|

| L-R spindle travel (X-axis) | 300 | mm | |

| Front-back spindle travel (Y-axis) | 200 | mm | |

| Vertical spindle travel (Z-axis) | 220 | mm | |

| Table tilt angle (A-axis) | 0~-95° | deg | |

| Table rotation (C-axis) | ±360° | deg | |

| Table working surface size | 250 x 250 (swing Φ300) | mm | |

| Table top surface shape | T-groove 14-8 direction | mm | |

| Maximum workpiece weight | 50 | kg | |

| Spindle speed (maximum) | Max. 40,000 (Other:12,000/15,000/20,000/30,000) | min-1 | |

| Rapid traverse rate | X-axis rapid traverse rate | 30 | m/min |

| Y-axis rapid traverse rate | 30 | m/min | |

| Z-axis rapid traverse rate | 25 | m/min | |

| A-axis rapid traverse rate | 8,000 | deg/min | |

| C-axis rapid traverse rate | 8,000 | deg/min | |

| Cutting feed speed | Cutting feed speed X-axis | 1~6,000 | m/min |

| Cutting feed speed Y-axis | 1~6,000 | m/min | |

| Cutting feed speed Z-axis | 1~6,000 | m/min | |

| Cutting feed speed A-axis | 1~5,000 | deg/min | |

| Cutting feed speed C-axis | 1~5,000 | deg/min | |

| Tool shank | *please refer to the catalog | ||

| Number of tools that can be stored | Max. 60(Other:24.40Number) | Number | |

| Tool selection method | Fixed location, random access | ||

| Maximum tool diameter | Φ52 | mm | |

| Maximum tool length | 150 | mm | |

| Maximum tool weight | 2.5 | kg | |

| Spindle motor | *please refer to the catalog | kw | |

| Spindle drive system | Built-Out/Built-in *please refer to the catalog | ||

| Total power capacity | 24 | KVA | |

| Air pressure source capacity | > 0.5 | Mpa | |

| Cutting oil tank capacity | 68 | L | |

| Unit height | 2,645 | mm | |

| Unit dimensions | 1,720×2,500 | mm | |

| Unit weight | 4,500 | kg | |

| Control device | FANUC 31i-B5 | ||

Machining centers with 5-axis control

Eguro's 5-axis machining centers feature a fully thermally symmetric design and a highly rigid gantry structure, enabling multi-faceted machining and 3D curved surface machining.

The E-32v is a compact, high-precision model that employs a trunnion structure to achieve both compactness and accuracy. The E-43v features increased X-axis travel, making it suitable for large workpieces. Unmanned production can also be realized through coordination with vertical multi-joint robots.

The unit provides an optimal solution for manufacturing sites seeking high machining precision and efficiency.

| Model | Rotation speed (rpm) | Stroke X-axis/Y-axis/Z-axis/A-axis/C-axis (mm) | Unit dimensions(mm) Width x depth x height | Weight (kg) |

|---|---|---|---|---|

| 10,000 | 370/320/320 +10°~-100°/±360° | 2,100×2,550×2,830 | 6,800 |