products

SANFLEX-8Special-purpose machining equipment

products

SANFLEX-8

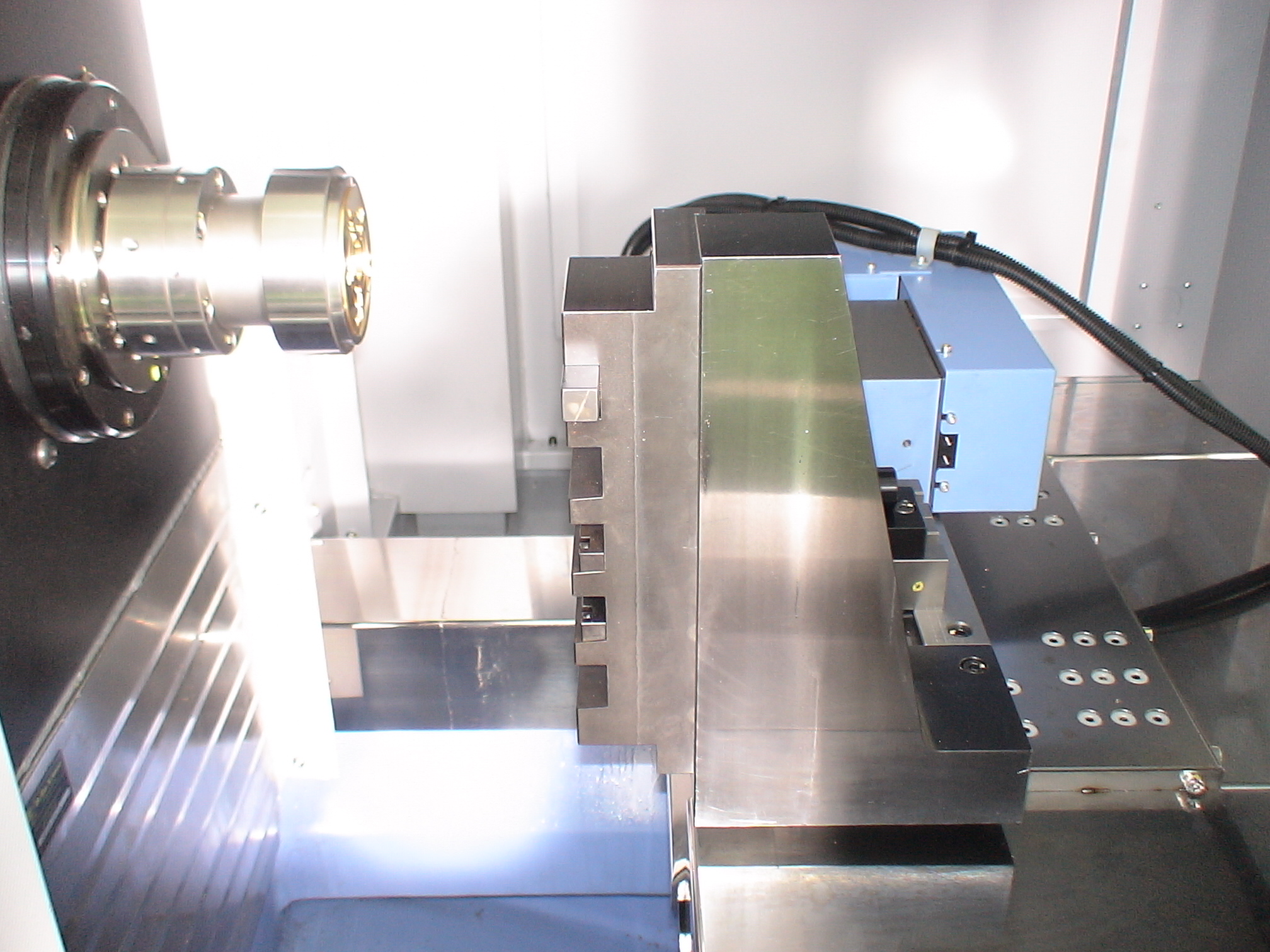

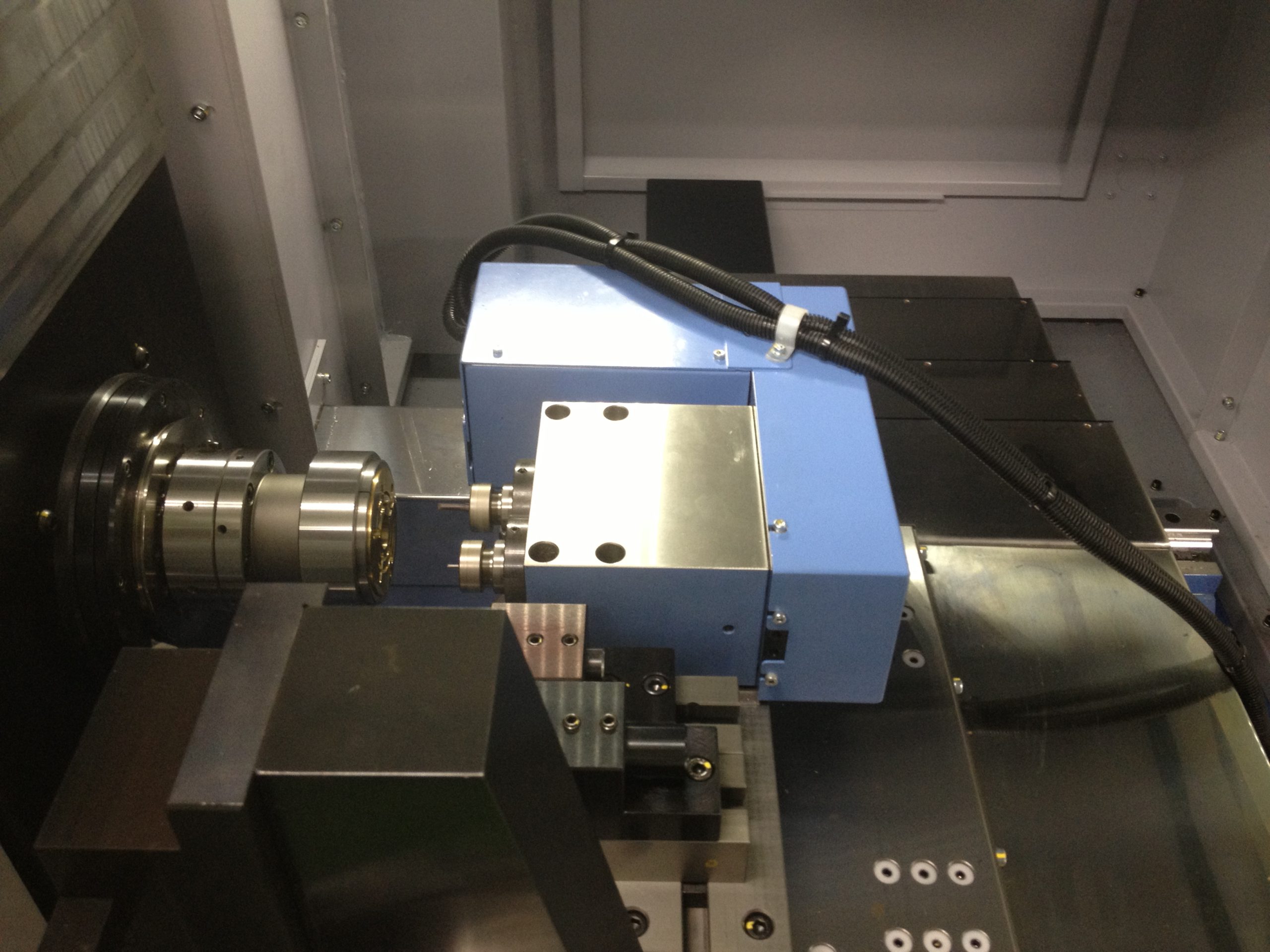

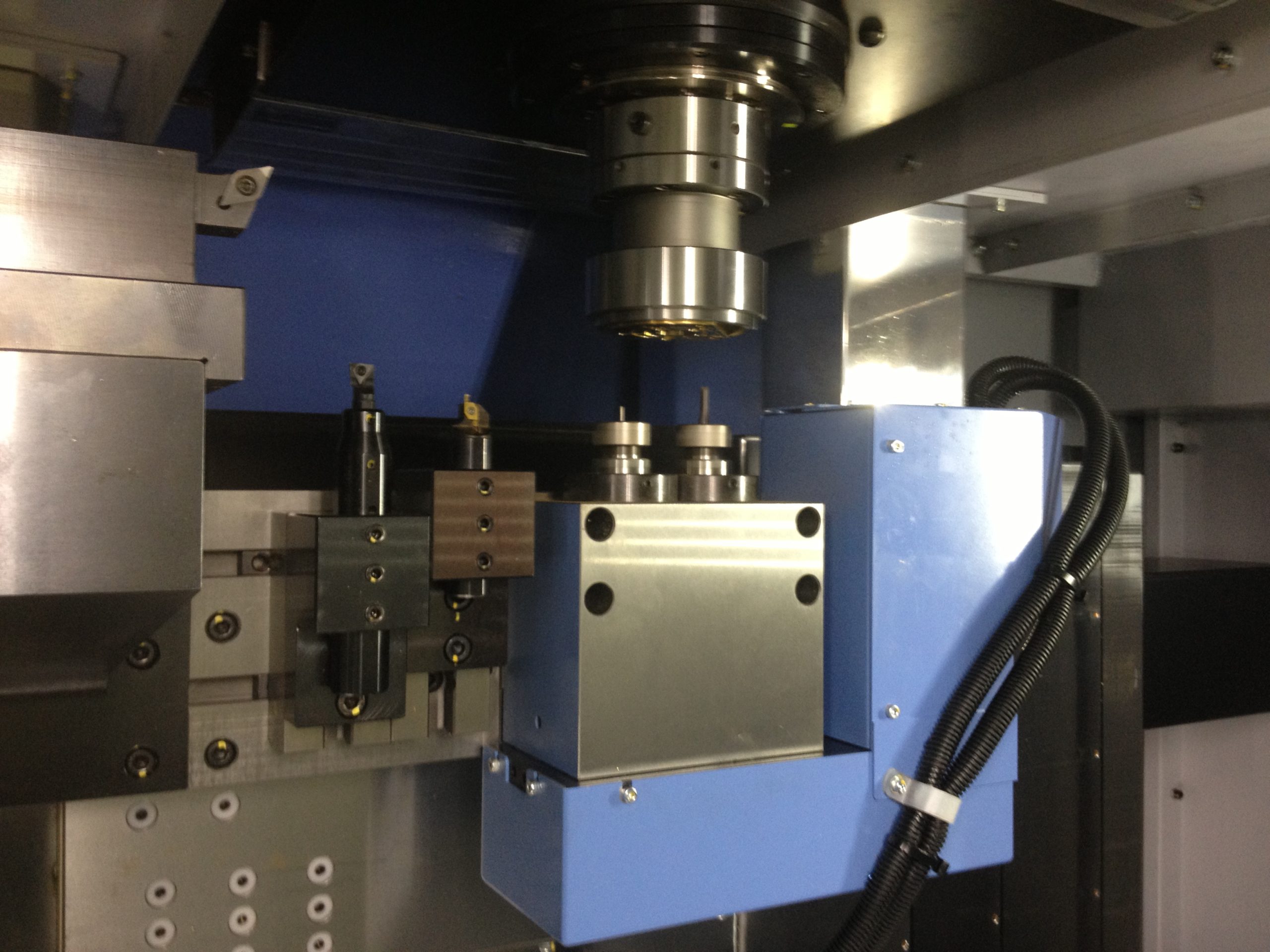

Y-axis control added to headstock:

Compound machining unit featuring high-precision gang-type configuration

High-precision 2+1 machining

- New compound machining with X and Z slide axes and a headstock that moves on the Y-axis

Highly flexible layout with multi-stage toolpost

- Combination of the built-in spindle with a variety of units enables compound machining

Stable structure

- Thermally symmetric design for stable, high-precision machining

For more information or inquiries about this product, please contact us here.

| Category | SANFLEX-8 | Unit | |||

|---|---|---|---|---|---|

| Capacity | Maximum machining range (diameter × length) | Φ60x80 | mm | ||

| Spindle | Rotation speed | Max6,000 | min-1 | ||

| Spindle nose | EDA-8 (No. 8 collet adapter) | ||||

| Collet diameter | MaxΦ20 | mm | |||

| Power chuck specifications | 4inch | ||||

| Slide | X-axis travel | 300 | mm | ||

| Y-axis travel | 200 | mm | |||

| Z-axis travel | 250 | mm | |||

| X-axis rapid traverse rate | 25 | m/min | |||

| Y-axis rapid traverse rate | 8 | m/min | |||

| Z-axis rapid traverse rate | 20 | m/min | |||

| Jog feed rater | 0~1,260 | mm/min | |||

| Toolpost | Gang-type | ||||

| Spindle motor output | 2.2 | KW | |||

| Power supply | 34 | KVA | |||

| Main unit specifications | Unit dimensions (width/depth/height) | 2,070/1,645/1,975 | mm | ||

| Weight | 3,000 | Kg | |||

| Control device | FANUC System | ||||

Double-end processing centers

EGURO's double-end processing centers are units of specialized machinery capable of simultaneously machining both ends of shaft-shaped materials at high speed and with high precision using work drives.

Machining both ends with single-chucking not only reduces the cycle time by about half compared to conventional machining methods that involve processing one side at a time, but ensures left-right machining precision with stability, as there is no need to reclamp workpieces. Attachment of a rotary tool also enables double-end compound machining.

Our lineup includes the SBS-Series for short materials and the BS-series for long materials.

| Model | Rotation speed (rpm) | Stroke X-axis/Y-axis/Z-axis/A-axis/C-axis (mm) | Unit dimensions(mm) Width x depth x height | |

|---|---|---|---|---|

| 4,000 | 80/150/150 | 2,060x1,660x1,500 | 1,250 | |

| BSF-A4 : 8,000 BSF-A3 : 3,800 | BSF-A4:80/150/150 BSF-A3 : 80/150/175 | 1,850/1,240/1,950 | 1,250 | |

| BSZ-1000:3,000 BSZ-380S:4,000 BSZ-500S/600S:4,500 | 260/-/200 | 2,730/1,500/1,900 | 2,000 | |

| 4,000 | 150/-/150 | 2,255/1,500/2,030 | 1,800 |

Multi-axis milling machine

EGURO's multi-axis milling machines are dedicated units for high-speed, high-precision drilling and milling.

The fixed spindles, with vertical and horizontal axes, enable 5-face machining, which not only reduces cycle times compared to ATC-type tool changes, but also enables high-precision machining with the lack of need for tool changes.

Models offering different vertical and horizontal axis configurations are available with different machining ranges and numbers of spindles, enabling the creation of dedicated machines to meet individual customers’ requirements.

| Model | Number of axes:Horizontal axes/vertical axes | Stroke X-axis/Y-axis/Z-axis/A-axis/C-axis (mm) | Unit dimensions(mm) Width x depth x height | |

|---|---|---|---|---|

| 230:2/3 320:3/2 430:4/3 | 230,320 : 270/150/150 430 : 390/150/150 | 230,320 : 1,240/1,595/1,900 430 : 1,245/1,650/2,010 | 230,320 : 1,500 430 : 2,000 |

Secondary processing machinery for forging and pressing

The MATE-6 is a high-productivity CNC lathe developed for secondary processing of industrial fasteners, capable of reducing cycle times and handling mass production.

It is equipped with a high-speed, single-arm loader that allows workpieces to be loaded and unloaded without stopping the spindle rotation, and a dedicated retrieval mechanism offering space-saving advantages with regards to workpiece supply and recovery.

It helps facilitate transitions from single-purpose units currently in use to the introduction of NC lathes.

| Model | Rotation speed (rpm) | Stroke X-axis/Z-axis (mm) | Unit dimensions (mm) Width x depth x height | Weight(kg) |

|---|---|---|---|---|

| 4,000 | 160/100 | 1,600/1,830/1,540 | 1,100 |

Knurling machine

The RGS-200 is a high-precision dedicated knurling machine. It can be recommended for replacing single-purpose knurling units and for achieving more beautiful and uniform decorative finishes.

Being equipped with NC control enables numerical control of knurling position changes due to gear exchanges,

as well as of modifications required for complex knurling processes, such as interlaced and diamond patterns, enabling easy setup changes.

In addition, it can perform both knurling and turning, enabling process integration and time savings by combining separate processes into one.

| Model | Rotation speed (rpm) | Stroke X-axis/Z-axis (mm) | Unit dimensions (mm) Width x depth x height | Weight(kg) |

|---|---|---|---|---|

| 3,000 | 300/150 | 1,400/1,060/1,480 | 1,200 |

High-precision processing machinery

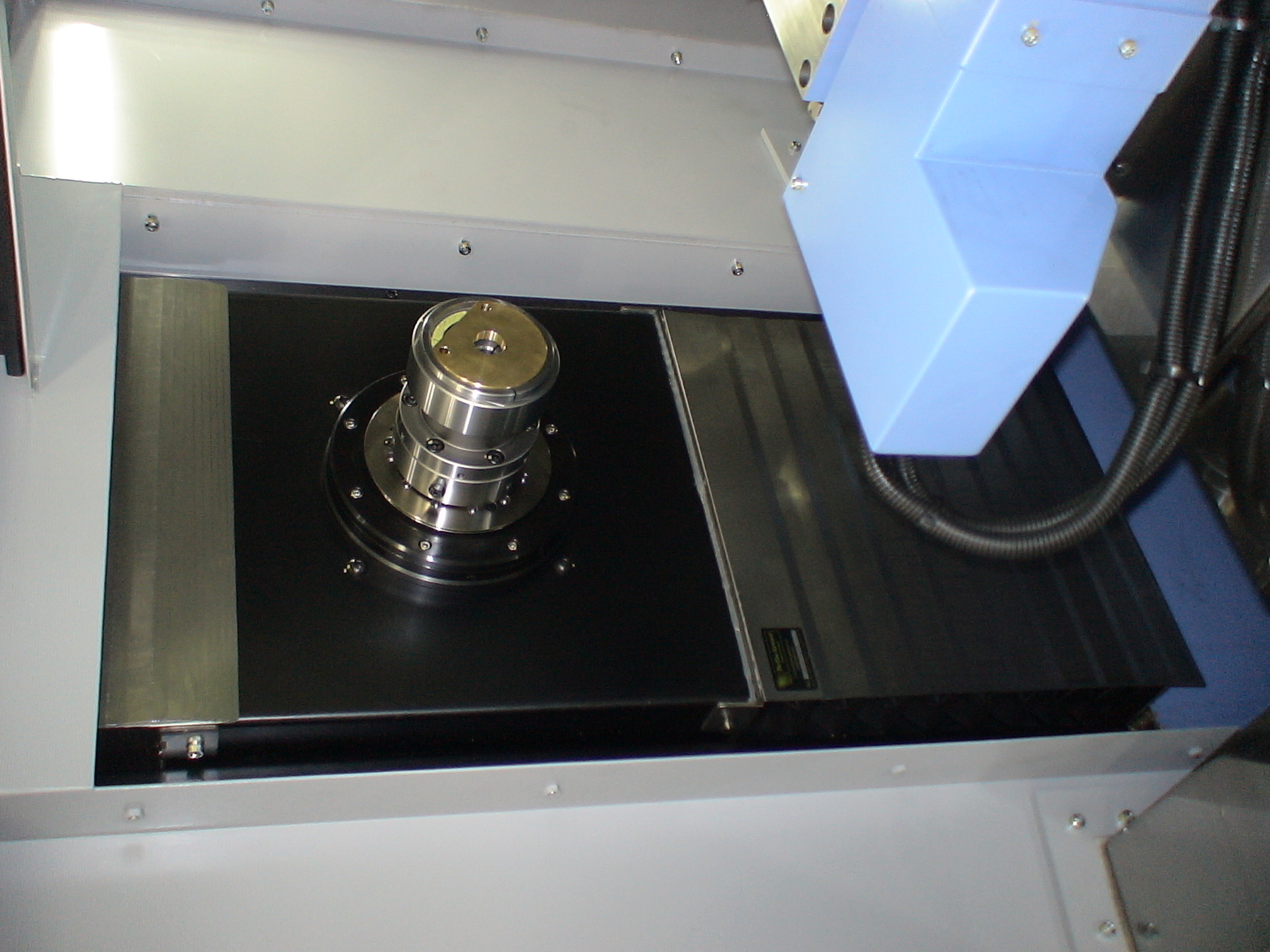

The 100-Nano is a high-precision processing machine that integrates traditional technologies with innovative ideas cultivated over many years to achieve EGURO’s highest level of precision machining.

The slide features independent X-axis and Z-axis structures, along with a double V-groove thermally sprayed with molybdenum, and a bed made of thermally symmetric artificial granite to prevent thermal deformation and vibration.

Featuring a built-in air static pressure spindle as well, the unit is ideal for workpieces requiring extremely high precision.

| Model | Rotation speed (rpm) | Stroke X-axis/Z-axis (mm) | Unit dimensions (mm) Width x depth x height | Weight(kg) |

|---|---|---|---|---|

| 5,000 | 200/125 | 1,175/990/1,710 | 900 |

Other machinery

ECOLA is a dedicated machine designed specifically for processing powder-based workpieces, featuring separation of the drive chamber and processing chamber. This makes the unit uniquely suited to processing challenging and troublesome materials such as ceramics, which generate powder during processing that can enter toolposts’ sliding surfaces and shorten the life of the machinery.

| Model | Rotation speed (rpm) | Stroke X-axis/Z-axis (mm) | Unit dimensions (mm) Width x depth x height | Weight(kg) |

|---|---|---|---|---|

| 5,000 | 300/150 | 1,600/1,260/1,755 | 900 |

Refurbished

| Model | Rotation speed (rpm) | Unit dimensions(mm) Width x depth x height | Weight(kg) |

|---|---|---|---|

| 5,000 | 420/390 | 2,100 |