products

SBS-400FDouble-end processing centers

products

SBS-400F

Short-length, double-end processing center with work drive

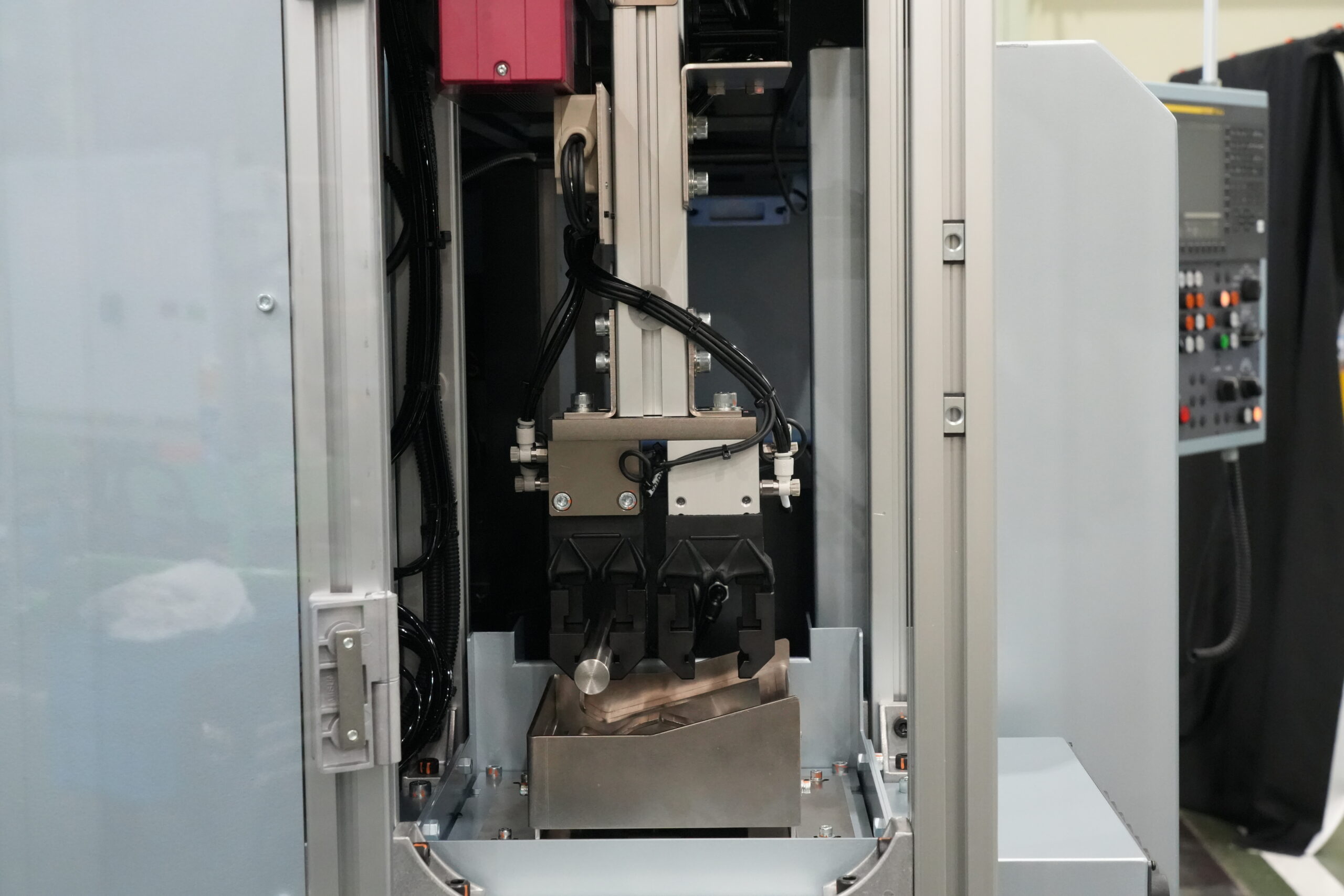

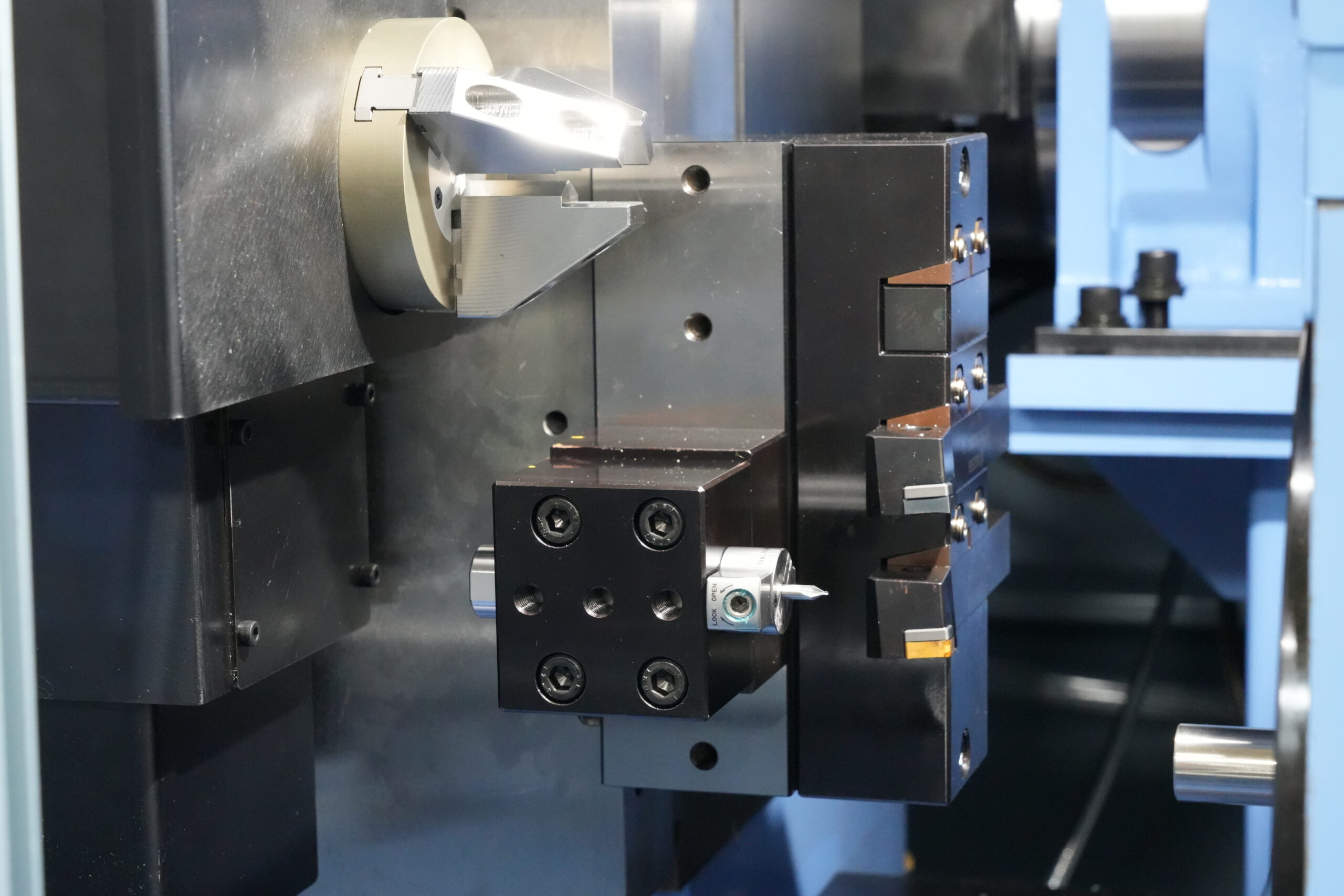

Simultaneous double-end machining

- Performs processing with independent left and right toolposts featuring 3-axis control

- Work drive grips blank centers to ensure stable coaxiality and runout accuracy

Facilitates high productivity

- Toolposts with 3-axis control enable compound machining with the addition of optional equipment

- Make selections based on gang-type/turret-type configurations and workpiece details

Specialized machine with unique features

- Compact dedicated machine; the product of extensive expertise in simultaneous double-end processing

- EGURO offers proposals of various methods for workpiece supply and recovery

For more information or inquiries about this product, please contact us here.

| Model name | SBS-400F | Unit | ||

|---|---|---|---|---|

| Capacity | Machining range (maximum diameter) | φ30 | mm | |

| Machining range (minimum diameter) | φ8 | mm | ||

| Machining range (maximum length) | 210 | mm | ||

| Machining range (minimum length) | 130 | mm | ||

| Spindle | Rotation speed | 4,000 | min-1 | |

| Output | AC2.2 | KW | ||

| Toolpost | Toolpost | Gang-type | ||

| Standard tool size | □12 | mm | ||

| X-axis travel | 80 | mm | ||

| Y-axis travel | 150 | mm | ||

| Z-axis travel | 150 | mm | ||

| X-axis rapid traverse rate | 8 | m/min | ||

| Y-axis rapid traverse rate | 10 | m/min | ||

| Z-axis rapid traverse rate | 15 | m/min | ||

| Main unit specifications | Unit height | 1,500 | mm | |

| Height from floor to spindle center | 915 | mm | ||

| Required floor space (width × depth) | 2,060x1,660 | mm | ||

| Power supply | 10 | KVA | ||

| Unit weight | 1,250 | kg | ||

| Control device | FANUC System | |||

Double-end processing centers

EGURO's double-end processing centers are units of specialized machinery capable of simultaneously machining both ends of shaft-shaped materials at high speed and with high precision using work drives.

Machining both ends with single-chucking not only reduces the cycle time by about half compared to conventional machining methods that involve processing one side at a time, but ensures left-right machining precision with stability, as there is no need to reclamp workpieces. Attachment of a rotary tool also enables double-end compound machining.

Our lineup includes the SBS-Series for short materials and the BS-series for long materials.

| Model | Rotation speed (rpm) | Stroke X-axis/Y-axis/Z-axis/A-axis/C-axis (mm) | Unit dimensions(mm) Width x depth x height | |

|---|---|---|---|---|

| BSF-A4 : 8,000 BSF-A3 : 3,800 | BSF-A4:80/150/150 BSF-A3 : 80/150/175 | 1,850/1,240/1,950 | 1,250 | |

| BSZ-1000:3,000 BSZ-380S:4,000 BSZ-500S/600S:4,500 | 260/-/200 | 2,730/1,500/1,900 | 2,000 | |

| 4,000 | 150/-/150 | 2,255/1,500/2,030 | 1,800 |