products

E-43vMachining centers with 5-axis control

products

E-43v

Reaching ever higher heights in high-precision machining:

Simultaneous 5-axis control for everything from multi-faceted machining to 3D curved surface machining

High precision

Thermally symmetric design structure and rigid gantry structure.

In addition, standard specifications include scales on three axes to ensure stable repeatability and tracking precision.

Compact design

The basic structure measures 1,000 × 1,225 mm and weighs 3.8 tons, offering a compact yet robust design.

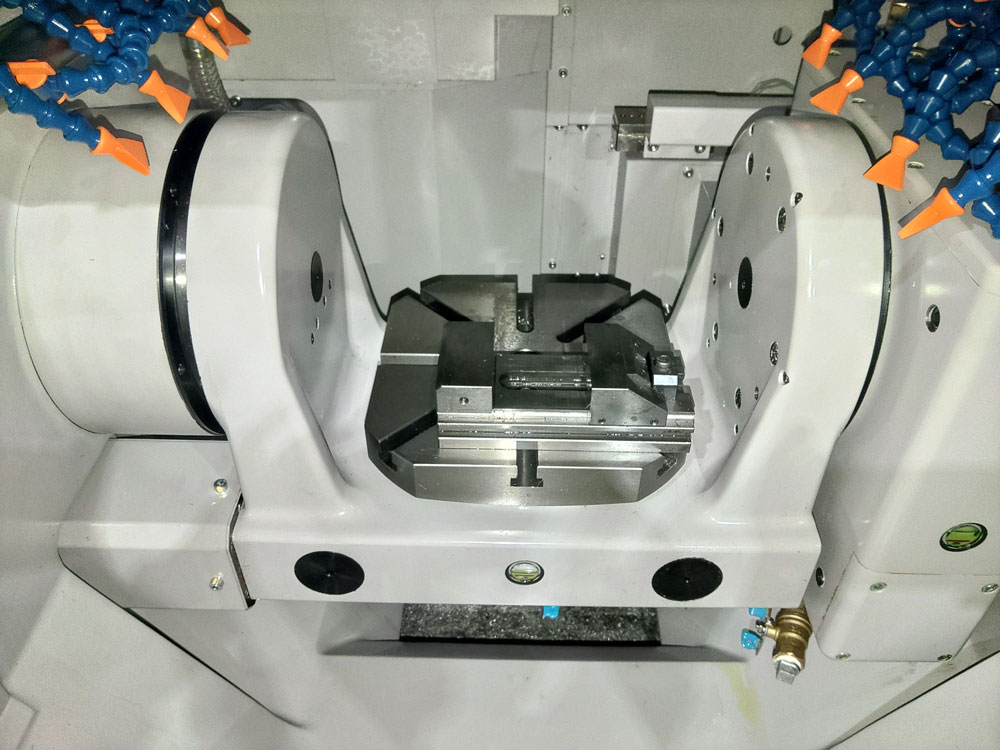

Maintains compactness and high precision through an innovative trunnion structure.

Automation compatibility

Selectable spindle specifications: See detailed spindle specifications table

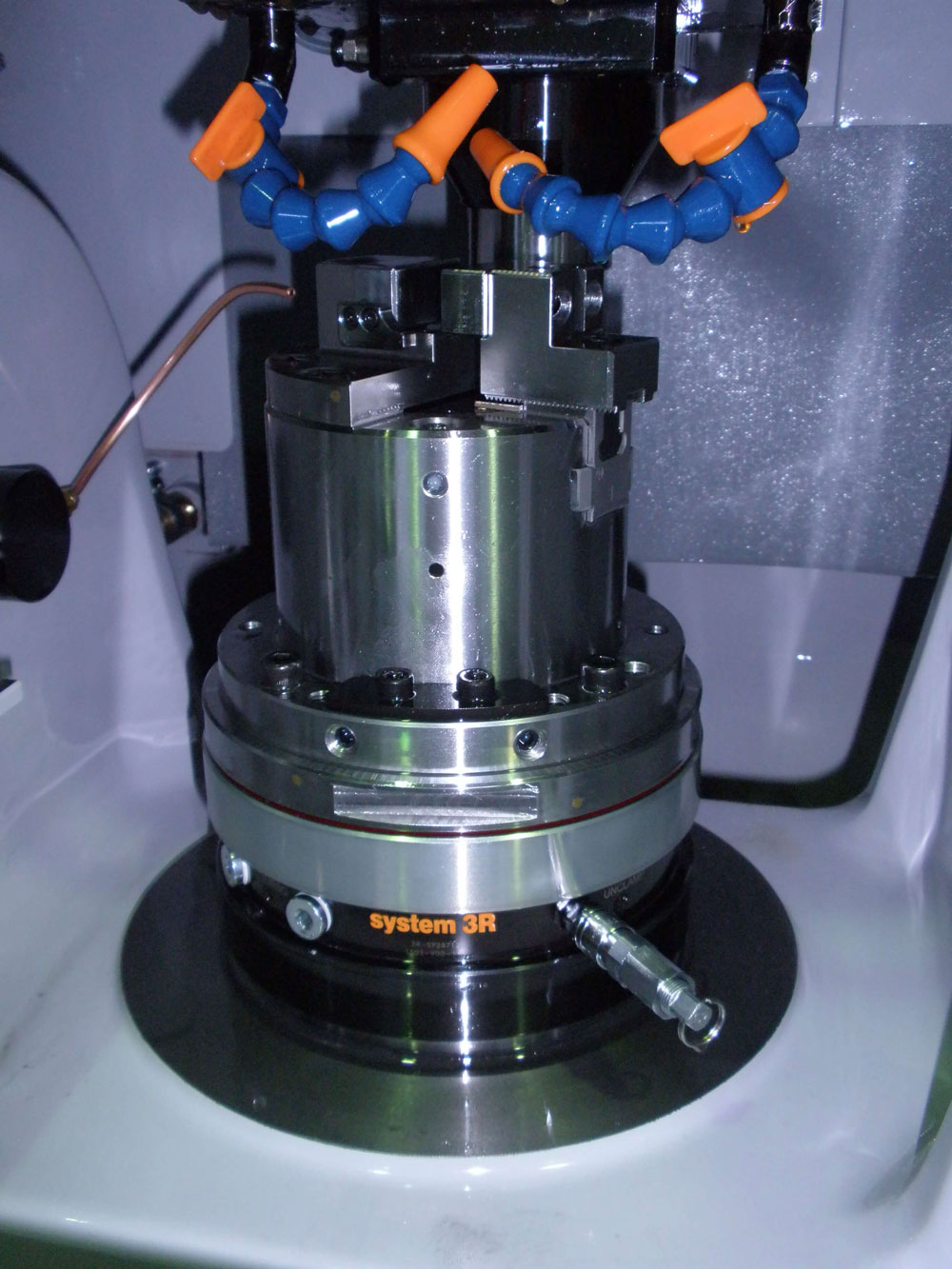

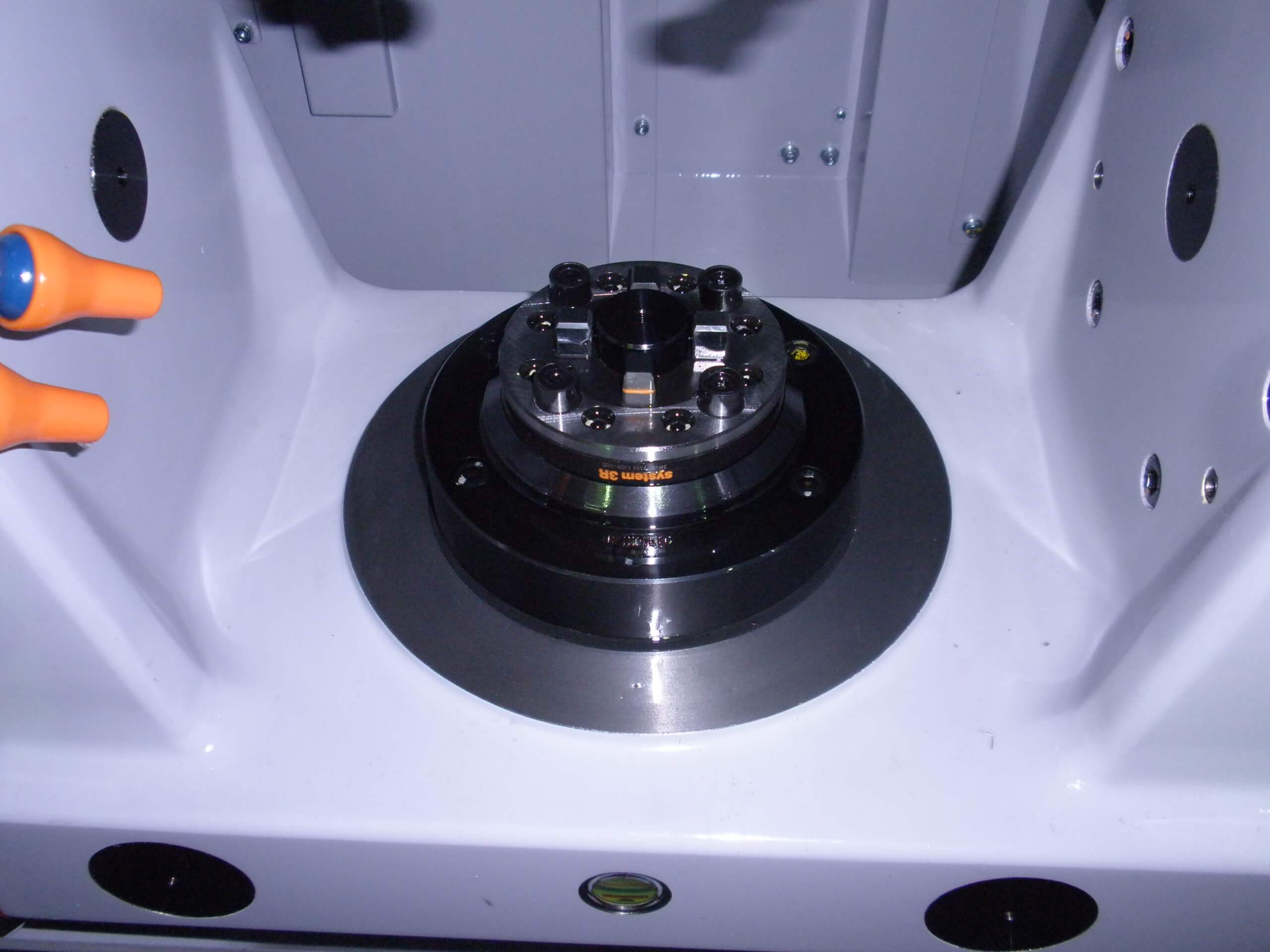

Tooling options tailored to application: Precision chuck (System3R MacroHP type, etc.)

Unmanned system (ROBO-Station) utilizing a vertical multi-joint robot

For more information or inquiries about this product, please contact us here.

| Category | E-43v | Unit | |

|---|---|---|---|

| L-R spindle travel (X-axis) | 370 | mm | |

| Front-back spindle travel (Y-axis) | 320 | mm | |

| Vertical spindle travel (Z-axis) | 320 | mm | |

| Table tilt angle (A-axis) | +10°~-100° | deg | |

| Table rotation (C-axis) | ±360° | deg | |

| Table working surface size | 315×315(Ф380) | mm | |

| Table top surface shape | T-groove 16-8 direction | mm | |

| Maximum workpiece weight | 100 | kg | |

| Spindle nose | 7/24 taper: CAT40 | ||

| Spindle speed (maximum) | 10,000 | min-1 | |

| Rapid traverse rate | X-axis rapid traverse rate | 24 | m/min |

| Y-axis rapid traverse rate | 24 | m/min | |

| Z-axis rapid traverse rate | 20 | m/min | |

| A-axis rapid traverse rate | 7,500 | deg/min | |

| C-axis rapid traverse rate | 10,000 | deg/min | |

| Cutting feed speed | Cutting feed speedX-axis | 1~8,000 | m/min |

| Cutting feed speedY-axis | 1~8,000 | m/min | |

| Cutting feed speedZ-axis | 1~6,500 | m/min | |

| Cutting feed speedA-axis | 1~2,500 | deg/min | |

| Cutting feed speedC-axis | 1~4,000 | deg/min | |

| Tool shank | BT40 | ||

| Pull stud | JIS-40P | ||

| Number of tools that can be stored | 24 | Number | |

| Tool selection method | Fixed location, random access | ||

| Maximum tool diameter | Φ115 | mm | |

| Maximum tool length | 225 | mm | |

| Maximum tool weight | 5 | kg | |

| Spindle motor | 5.5/7.5 | kw | |

| Spindle drive system | Built-in | ||

| Total power capacity | 36 | KVA | |

| Air pressure source capacity | > 0.5 | Mpa | |

| Cutting oil tank capacity | 75 | L | |

| Unit height | 2,830 | mm | |

| Unit dimensions | 2,100×2,550 | mm | |

| Unit weight | 6,800 | kg | |

| Control device | FANUC 31i-B5 | ||

Machining centers with 5-axis control

Eguro's 5-axis machining centers feature a fully thermally symmetric design and a highly rigid gantry structure, enabling multi-faceted machining and 3D curved surface machining.

The E-32v is a compact, high-precision model that employs a trunnion structure to achieve both compactness and accuracy. The E-43v features increased X-axis travel, making it suitable for large workpieces. Unmanned production can also be realized through coordination with vertical multi-joint robots.

The unit provides an optimal solution for manufacturing sites seeking high machining precision and efficiency.

| Model | Rotation speed (rpm) | Stroke X-axis/Y-axis/Z-axis/A-axis/C-axis (mm) | Unit dimensions(mm) Width x depth x height | Weight (kg) |

|---|---|---|---|---|

| Max. 40,000(12,000 / 15,000 / 20,000 / 30,000) | 300/200/220 0~-95°/±360° | 1,720×2,500×2,645 | 4,500 |