products

SANAX-10CNC lathes featuring toolposts with 3-axis control

products

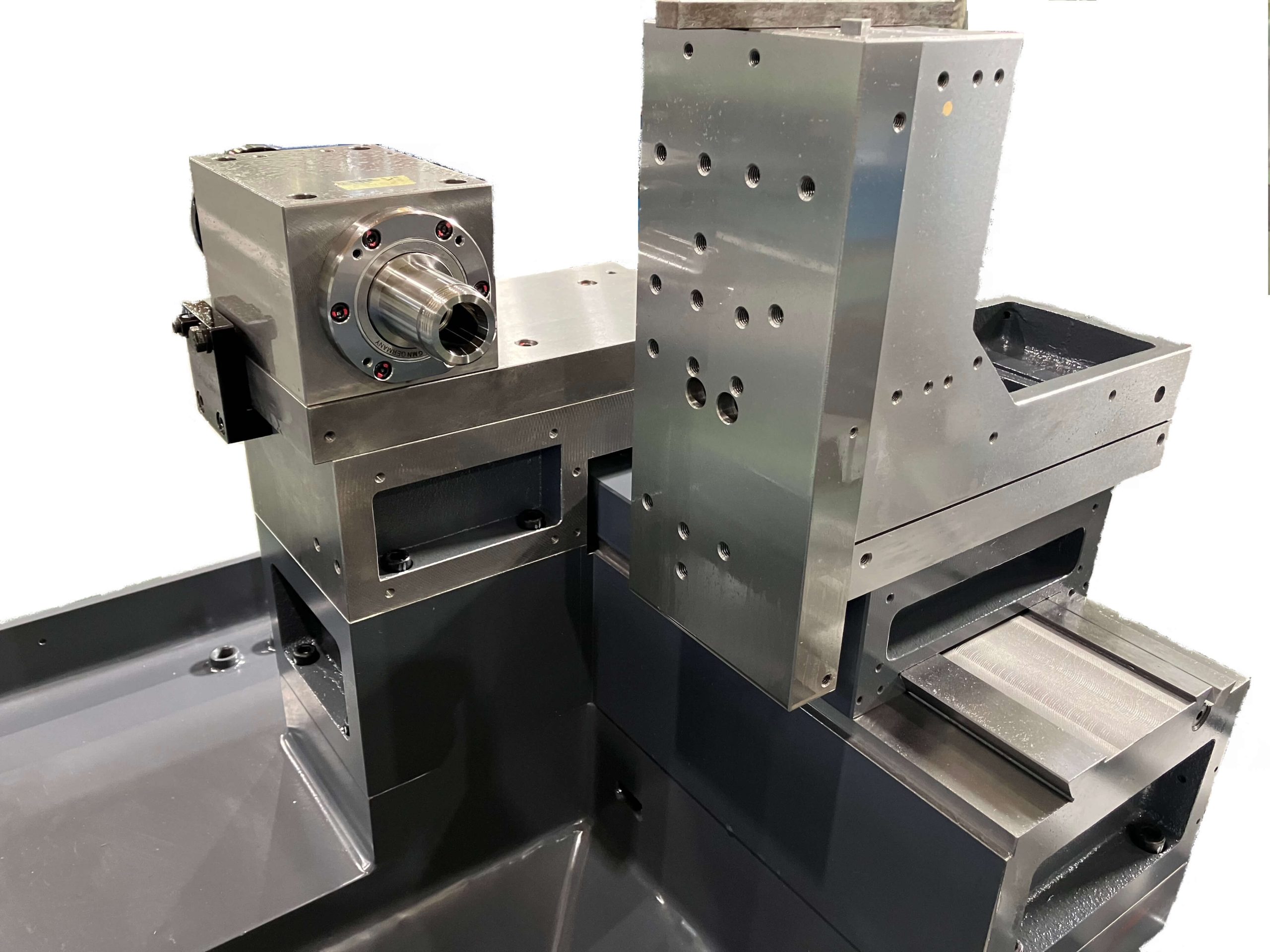

SANAX-10

High-precision gang-type toolpost with 3-axis control enables compound machining

3-axis toolpost ensures versatility

- Extending the slide stroke from the SANAX-6 to increase the number of tools that can be mounted enables complex machining

High precision

- Revised spindle specifications offer support for a wider range of workpieces and materials

Compound machining

- Can be equipped with various specifications including spindle indexing, optional equipment, and bar material supply, making it ideal as a base unit for gang-type automatic processing machines.

For more information or inquiries about this product, please contact us here.

| Category | SANAX-10 | Unit | |||

|---|---|---|---|---|---|

| Machining range | Maximum machining range (diameter × length) | Φ80x60 | mm | ||

| Outer diameter tool holder (Ref. value) | □16 x 5 pieces | mm | |||

| Inner diameter tool holder (Ref. value) | Φ25x5Number | mm | |||

| Spindle | Rotation speed | Max6,000 | min-1 | ||

| Speed conversion ratio | Stepless S4-digit direct command | ||||

| Spindle nose | EDA-10 (No. 10 collet adapter) | ||||

| Collet diameter | Φ25.5 | mm | |||

| Power chuck specifications | 5inch | ||||

| Slide | X-axis travel | 100 | mm | ||

| Y-axis travel | 175 | mm | |||

| Z-axis travel | 300 | mm | |||

| X-axis rapid traverse rate | 10 | m/min | |||

| Y-axis rapid traverse rate | 12 | m/min | |||

| Z-axis rapid traverse rate | 15 | m/min | |||

| Jog feed rater | 0~1,260 | mm/min | |||

| Motor output | Spindle | 3.7/2.2 (15-minute rating/continuous) | KW | ||

| Toolpost | X-axis | 2.5 | |||

| Y-axis | 2.5 | ||||

| Z-axis | 2.7 | ||||

| Power supply | 10.0 | KVA | |||

| Main unit specifications | Unit dimensions (width/depth/height) | 1,640/1,195/1,640 | mm | ||

| Height from floor to spindle center | 930 | mm | |||

| Weight | 1,800 | Kg | |||

| Control device | FANUC System | ||||

CNC lathes featuring toolposts with 3-axis control

EGURO's 3-axis CNC lathes are equipped with a simple 2-axis slide structure and a vertical Y-axis.

The three-dimensional toolpost further reduces space requirements.

Adding a rotating tool also enables compound machining such as turning plus hole-punching/milling.

In addition, with its employment of two opposing spindles, the SANATURN series features an expanded processing range with the ability to perform swaging/upsetting while extracting large workpieces, as well as to reduce workpiece deflection by synchronizing the rotation of the opposing spindles.

| Model | Rotation speed of first/second spindles (rpm) | Stroke X-axis/Y-axis/Z-axis/A-axis (mm) | Unit dimensions(mm) Width x depth x height | Weight(kg) |

|---|---|---|---|---|

| 12,000/- | 50/105/150/- | 840×980×1,525 | 550 | |

| 12,000/5,000 | 50/105/165/160 | 1,730×1,005×1,555 | 980 | |

| 5,000/5,000 | 100/170/300/300 | 1,935×2,185×1,840 | 2,500 |